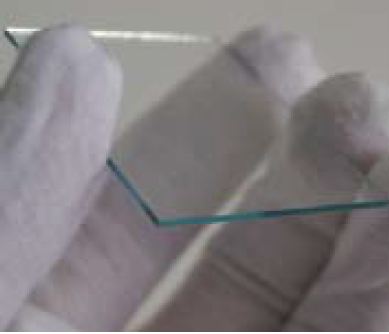

| Introduction: | Whenever an electrically conductive surface that at the same time offers a high optical transparency is required, ITO-coating glass series are used. ITO-coating glass is achieved by sputter-coating a thin conductive layer of indium-tin-oxide onto high quality glass substrates. The conductive transparent ITO glass is often used for display technology and micro structuring applications. Other typical applications based on our ITO-glass are the manufacturing of transparent ITO-electrodes, integrated invisible flat antennas, antistatic windows, heating and de-icing windows with an optical function, far infrared mirrors and many other unique technical appliances.

MOQ = 50pcs |